- P.O. Box 1067

San Marcos, TX 78667 USA - 512.827.3701

Products Details

AUTOFLUX

Self-Cleaning Drum Filters

Introducing our state-of-the-art Autoflux self-cleaning drum filters – an innovative solution designed for the filtration of both magnetic and non-magnetic pollutants. Engineered to handle significant volumes of industrial coolant within minimal floor space, these filters excel in achieving efficient filtration while ensuring a reduced environmental footprint. The filtration efficiency of Autoflux drum filters is entirely customizable, tailored to your machining demands through the utilization of permanent filter nets.

Unlock the potential of optimal filtration by combining Autoflux drum filters with Automag magnetic separators, amplifying the efficiency of industrial coolant filtration. With the flexibility to implement both single-machine solutions and centralized setups, Autoflux self-cleaning drum filtration systems provide adaptable answers to your coolant filtration needs.

Experience the freedom of REDUCED FLOOR SPACE as Autoflux self-cleaning drum filters treat substantial coolant volumes within a compact footprint. With the use of permanent stainless steel filter mesh, these filters eliminate the need for consumables, providing a cost-effective and sustainable solution. VERSATILE and customizable, Autoflux self-cleaning drum filters offer an array of models that seamlessly match your machine tool, ensuring optimal filtration efficiency aligned with your machining requirements.

Available in four models, the range spans flow rates from 300 to 1000 l/m (emulsion) and 150 to 500 l/m (neat oil), catering to diverse needs across machining processes.

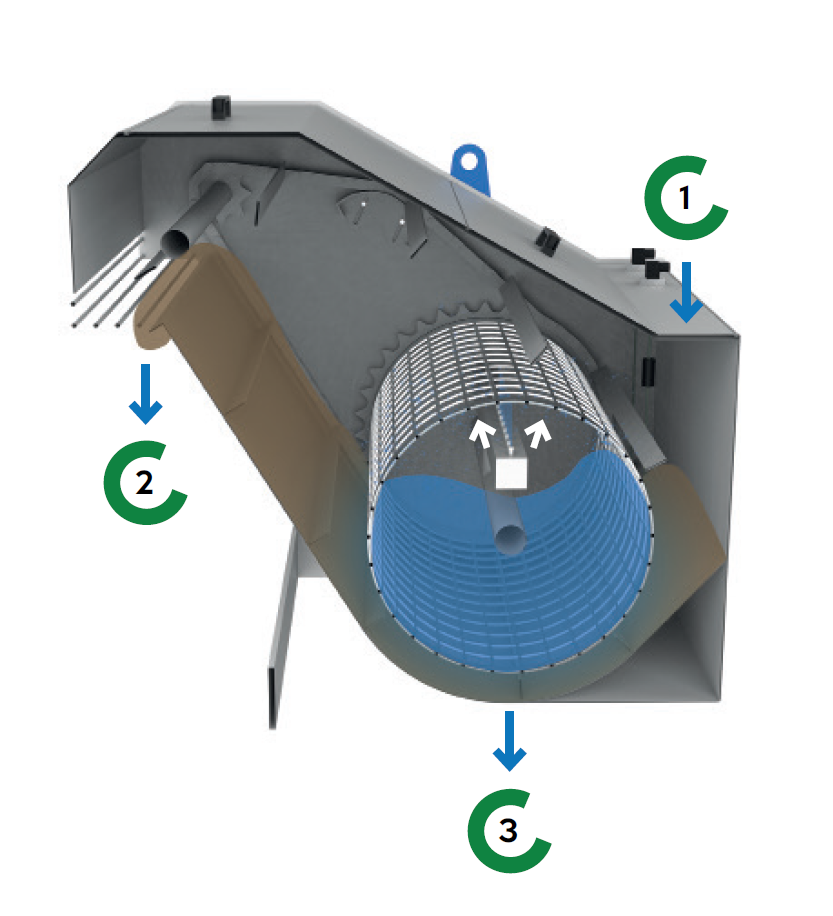

Working Process:

- Dirty Coolant Entry:Contaminated industrial coolant is guided into the Autoflux drum filter and passes through a stainless steel mesh enveloping the drum’s surface. Pollutants are effectively captured by the mesh during this initial phase.

- Filtration Process: As pollutants accumulate on the drum filter’s mesh, the thickness of the sludge intensifies, enhancing filtration efficiency while raising the liquid level. Once the liquid level reaches its maximum, the mesh cleaning cycle initiates. Nozzles spray clean liquid from the drum’s interior to its exterior, dislodging, and flushing contaminants. A dredging chain positioned at the filter’s bottom effectively scrapes settled pollutants into a dedicated container.

- Clean Coolant Exit: : After traversing the filtering mesh within the drum, the purified liquid exits through the discharge area, ultimately collecting in an underlying reservoir. From this point, the cleansed liquid is routed back to your machine tools, ensuring uninterrupted workflow.

Immerse your operations in the efficiency of Autoflux self-cleaning drum filters – where innovation meets precision, ensuring a cleaner and more sustainable machining environment.