- P.O. Box 1067

San Marcos, TX 78667 USA - 512.827.3701

Products Details

INDEX

Index filters

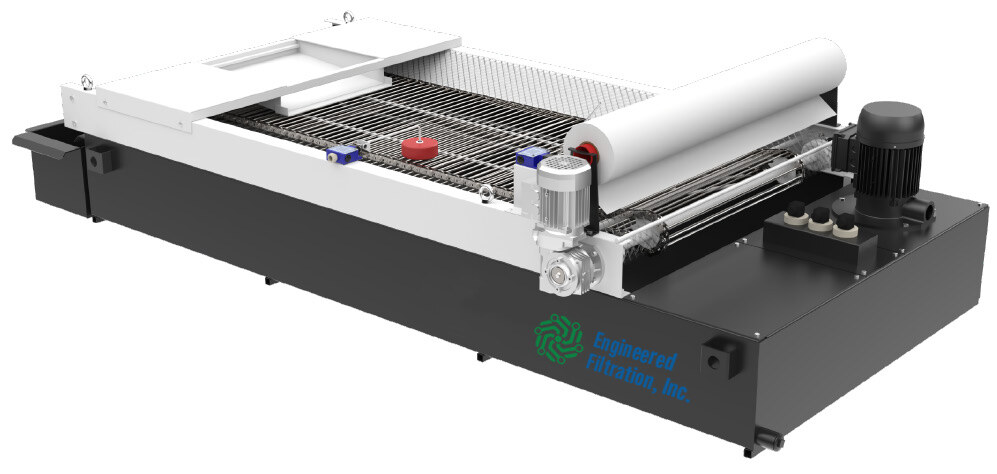

Experience the exceptional filtration capabilities of our Gravity Index filters, designed to provide optimal performance for both emulsions and neat oil. With a filtration grade range of 50 to 10 microns, determined by the choice of filter fabric, these filters offer versatility and efficiency in coolant filtration. When combined with our AUTOMAG magnetic separators, you can achieve enhanced filtration grades for industrial coolants while minimizing filter fabric consumption.

Choose from a diverse selection of Gravity Index filter models to precisely match your machine tool’s coolant filtration needs. Avoid inefficiencies and excessive consumptions with the ability to customize the filtration system to your specific requirements. The Gravity range ensures the right coolant filtration system is seamlessly integrated, offering reliable and effective performance, thanks to Engineered Filtration Inc.’s meticulous research and engineering expertise.

The GRAVITY series, part of our indexing media coolant filters, represents a versatile solution for machine tool coolant filtration. The meticulously perfected design of the GRAVITY coolant filter is a result of thoughtful research and smart engineering, delivering consistent and dependable indexing media filtration. These coolant filters cater to various metalworking and grinding machines, accommodating emulsions and whole oils at different flow rates, while filtration levels are tailored to suit the filter media used.

Applications encompass a wide range, including centerless grinding, surface grinding, creep feed grinding, ID grinding, OD grinding, abrasive belt grinding, and cutoff saw coolant filtration.

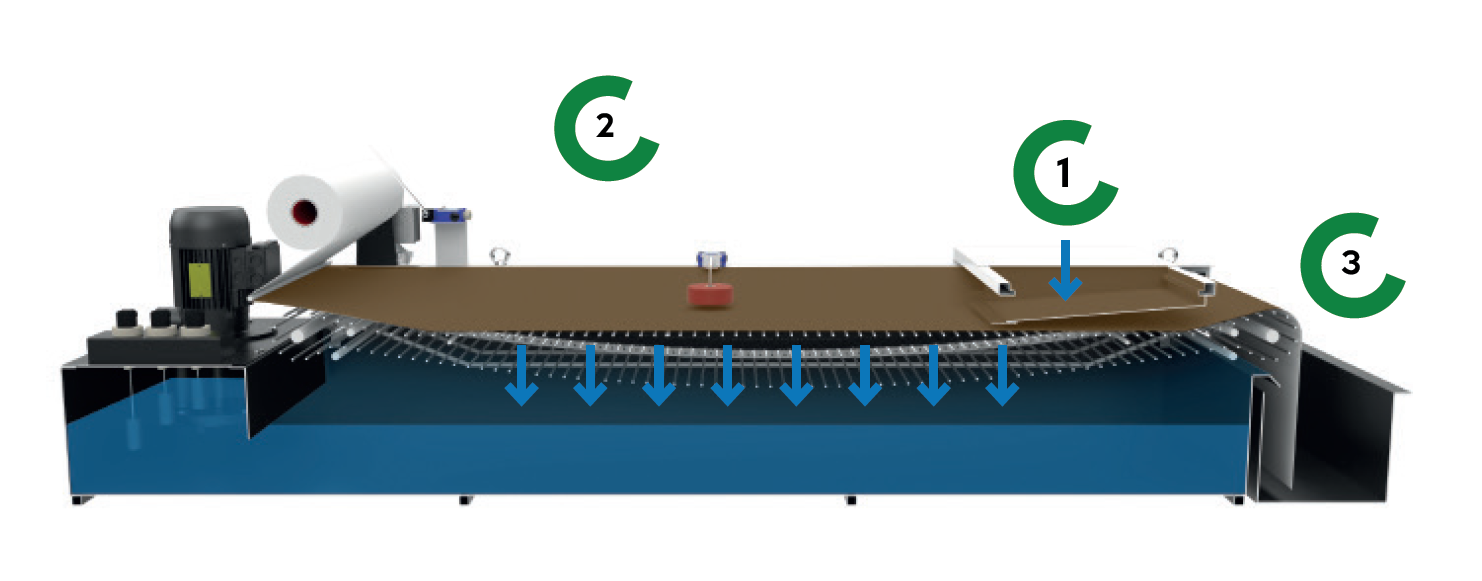

Working Process:

- Dirty Coolant Entry: Contaminated coolant is introduced through the coolant inlet of the Index filter, where it spreads across the filter fabric. Pollutant particles are captured, allowing clean coolant to flow into the clean coolant containment tank.

- Filtration Process: The filter fabric gradually collects pollutants until clogged. When the coolant cannot pass through the saturated fabric, the liquid level rises, activating a float mechanism. This float initiates the advancement of the filter fabric, replacing the used material with new fabric.

- Recycling of Filtered Coolant: The used filter fabric is collected in a dedicated tank for disposal, while the clean coolant can be efficiently pumped back to the machine tool for continued use.

Experience the unmatched efficiency and reliability of Gravity coolant filters, designed to optimize your machining operations, and maintain pristine coolant quality.