- P.O. Box 1067

San Marcos, TX 78667 USA - 512.827.3701

Product Categories

Products Details

Lakos

LAKOS CENTRIFUGAL SEPARATORS FOR INDUSTRIAL FLUID SOLUTIONS

Where It Works

Pre-Filtration

Using a LAKOS Separator as a pre-filter prior to finer filtration improves efficiency and minimizes liquid loss. As a result:

- Reduce disposal cost

- Minimize labor, maintenance downtime and filter media replacement costs

- Extend the life of finer filtration and water treatment systems

- Increase the life of filter cartridges and bags and eliminates water treatment processes

Protect Heat Exchangers

LAKOS Separators offer effective protection for heat exchangers against fouling. As a result:

- Maintain design efficiencies for better heat transfer rates = energy savings

- Reduce maintenance frequency for heat exchanger equipment

- Remove suspended grit and scale

Protect Spray Nozzles

LAKOS Separators removes solids that clog spray nozzles and other small orifices. This helps to:

- Maintain original nozzle design for efficient spray coverage

- Prevent wear abrasion and clogging – reducing frequency of nozzle replacement

- Maintain overall product quality through cleaner nozzles, reducing the need to scrap product due to quality

Reduce Waste

LAKOS Separators remove solids from liquids in your industrial process and allow reuse of the liquid. As a result:

- Reduce disposal cost

- Extends the life of process liquids by removing troublesome solids

- Concentrates solids for easy disposal or allows for recovery of high value solids

- Reduces replacement of downstream filter elements/media

- Improve water chemistry

- Extend the life of pump seals, valves, and process equipment

Prevent Solids Accumulation in Sumps and Basins

Using a LAKOS Separator as part of your process cooling system minimizes accumulation of solids that typically settle in sumps and basins. As a result:

- Fewer shutdowns

- Reduces solids build-up and decreases clean out time

- Avoids solids-induced microbial growth, decreases chemical use, and increases process liquid life

What LAKOS Removes

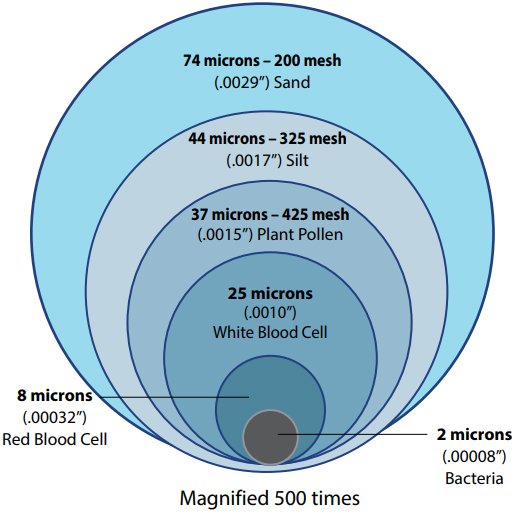

Effective Separator operation depends upon the difference in specific gravity between solids and the liquid. The greater the difference - the higher the removal efficiency.

Human hair thickness: .0016 (40 microns)

In addition to specific gravity, particle size affects separation efficiency. To gain perspective, 40 micron is at the visibility threshold. LAKOS Separators are highly effective at removing solids 44 micron and larger at specific gravity 2.6 and greater.

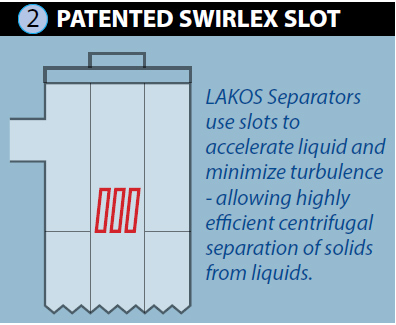

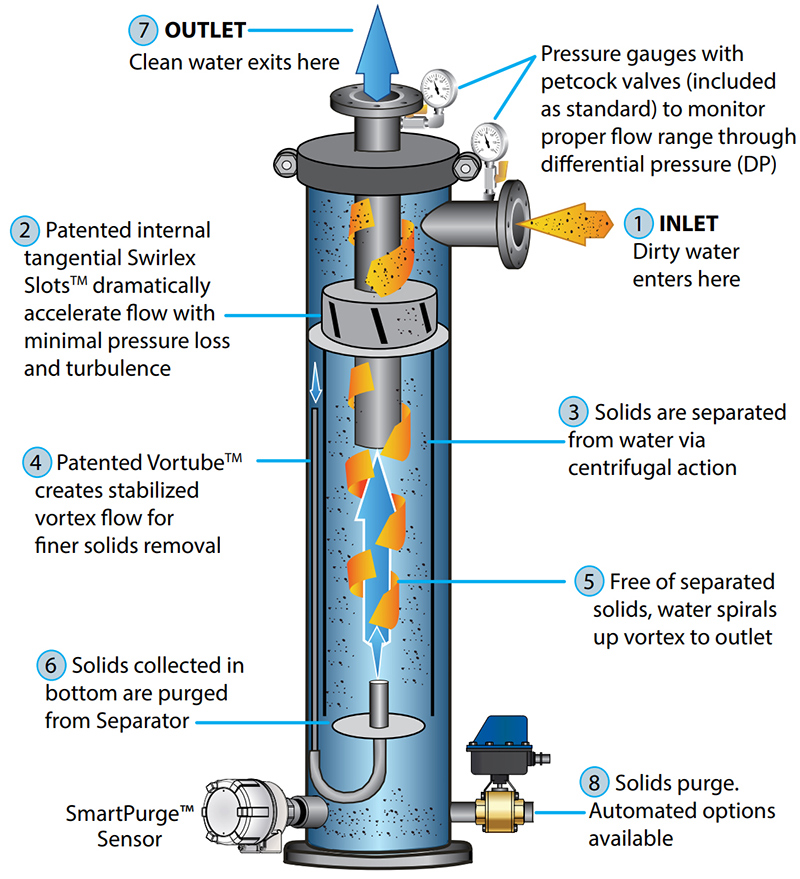

LAKOS Separators use slots to accelerate liquid and minimize turbulence - allowing highly efficient centrifugal separation of solids from liquids

Commonly Separable Materials and Specific Gravities

| Aluminum | 2.7 | Iron | 7.8 |

| Ashes (Coal) | 2.0 | Lead | 11.3 |

| Brass | 9.0 | Limestone | 2.8 |

| Bronze; Copper | 8.9 | Manganese | 7.4 |

| Carbon; Concrete; Lava | 1.8 - 2.5 | Mill Scale | 5.4 - 6.1 |

| Coal (Anthracite) | 1.3 - 1.9 | Nickel | 8.9 |

| Earth (Silt; Soil) | 1.2 - 2.0 | Sand; Silica; Shale | 2.6 - 2.8 |

| Glass (Crystal) | 3.0 | Steel | 7.8 |

| Granite; Gravel | 2.5 - 3.0 | Tin Ore | 6.4 - 7.0 |

| Graphite | 2.3 | Water | 1.0 |

Benefits of LAKOS Centrifugal Separators:

- Continuous, uninterrupted filtration removal (no standby equipment required)

- Single pass predictability as high as 98% of 44 microns, given solids with specific gravity of 2.6 and water at 1.0

- No screens or filter elements to plug/fill

- Zero to minimal liquid loss

- Increases productivity/process efficiency

- Lowers energy costs

- Reduces maintenance costs/ extends equipment life

- Conveniently handles waste

- Lowers health risks

- Reduces fluid and/or pressure loss

- Concentrated solids for easy handling

How It Works

LAKOS eJPX Separators feature improved internals and increased efficiencies as compared to our JPX Separators. To learn more about how our JPX Separators operate, see LAKOS Literature LS-631and LS-632.